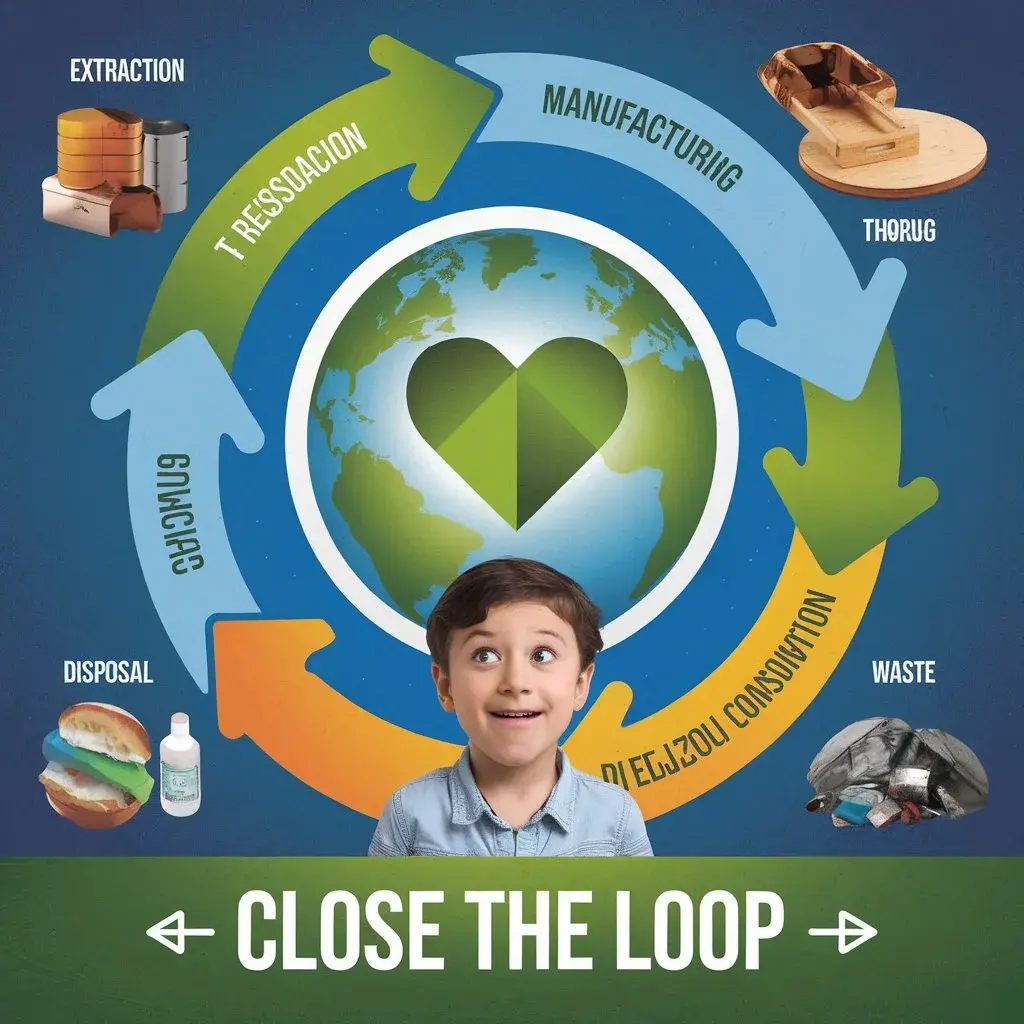

Close the loop is one of the best solutions we have. It’s a concept that allows businesses and individuals to keep materials and resources in use for as long as possible. Instead of throwing things away, we find ways to reuse, recycle, and repurpose them. This is the heart of the circular economy, a system where nothing is wasted, and everything has a purpose.

The world around us is changing fast, but not always for the better. As businesses grow and industries expand, the amount of waste we produce has skyrocketed. Resources like water, metals, and energy are being used at an unsustainable rate, while more and more waste is being dumped into landfills or oceans. So, what can we do about it?

In this article, we’ll explore what closing the loop means, why it matters, and how businesses can adopt this practice to build a more sustainable future. We’ll also look at real-world examples and provide actionable tips on how to transition to a circular economy.

What is a Closed-Loop System?

At its core, a closed-loop system ensures that nothing is wasted. In a typical linear economy, resources are taken from the earth, used to make products, and then discarded as waste. In a closed-loop system, however, every part of the production process is designed to reuse materials, recycle waste, and reduce the need for new raw materials.

The Linear vs. Circular Economy

In a traditional linear economy, we follow a take-make-dispose model. Raw materials are extracted from the environment, used to create products, and once those products are no longer useful, they’re thrown away. This system has led to excessive waste generation and the depletion of natural resources.

A circular economy operates differently. Instead of following a straight line, it’s like a circle. Materials are designed to be reused or repurposed, and waste is minimized or even eliminated. Products are made with the idea that they can be taken apart, repaired, or turned into something else at the end of their life cycle.

Product Lifecycle Management

In a closed-loop system, the focus shifts to managing the entire product lifecycle—from design to disposal. By thinking about how a product will be used and what happens to it after it’s no longer needed, businesses can design products that last longer, are easier to repair, and can be recycled into new materials.

Why Closing the Loop Matters

The benefits of closing the loop are vast, not just for businesses but for the environment and society as a whole. Let’s take a look at some of the key reasons why this practice is so important.

Reducing Waste

One of the biggest problems we face today is the amount of waste we produce. Every year, millions of tons of waste are sent to landfills or incinerated, contributing to pollution and greenhouse gas emissions. By closing the loop, businesses can significantly reduce the amount of waste they generate.

For example, instead of discarding used materials, businesses can find ways to reuse them in their production processes or recycle them into new products. This not only reduces the need for new raw materials but also minimizes the environmental impact of waste disposal.

Conserving Resources

The earth’s resources are finite. By continuing to rely on raw materials, we risk depleting the resources we need to survive. Closing the loop helps conserve valuable resources by keeping them in circulation. Instead of constantly extracting new materials, we can use the ones we already have.

This is particularly important for industries that rely on rare or non-renewable resources. By focusing on resource efficiency, businesses can reduce their dependence on raw materials and ensure a more sustainable future.

Reducing Environmental Impact

One of the biggest benefits of closing the loop is its positive impact on the environment. By reducing waste and conserving resources, businesses can minimize their contribution to pollution, climate change, and other environmental problems.

For example, manufacturing products from recycled materials often requires less energy and produces fewer emissions than making them from raw materials. This helps reduce the overall environmental footprint of the production process.

Boosting Innovation and Competitiveness

Adopting a circular economy mindset can also drive innovation and make businesses more competitive. By finding new ways to use resources and reduce waste, companies can differentiate themselves from competitors and attract environmentally conscious customers.

Moreover, businesses that invest in sustainable practices often find new opportunities for growth. Whether it’s developing new products from recycled materials or creating more efficient processes, closing the loop can lead to long-term success.

Key Elements of a Close-Loop System

To successfully close the loop, businesses need to focus on a few key elements. These elements are the building blocks of a circular economy and help ensure that resources are used as efficiently as possible.

Sustainable Product Design

A key part of closing the loop is designing products that can be easily recycled, repaired, or reused. This means thinking about the entire life cycle of a product from the very beginning.

For example, some companies use cradle-to-cradle design, which ensures that products can be taken apart and repurposed at the end of their life. By making products with fewer materials and simpler construction, businesses can make it easier to close the loop and reduce waste.

Circular Supply Chains

In a closed-loop system, it’s not just about what happens within a business—it’s also about the entire supply chain. A circular supply chain involves working with suppliers who are committed to sustainable practices and who prioritize recycling and resource efficiency.

By building a supply chain that embraces circular economy principles, businesses can reduce waste at every stage of the process—from sourcing materials to manufacturing, packaging, and distribution.

Recycling and Reuse Models

Another essential part of closing the loop is establishing systems for recycling and reuse. This could mean creating take-back programs for customers to return old products, or it could involve working with recycling facilities to ensure that used materials are processed properly.

In some industries, businesses are even experimenting with product-as-a-service models, where customers rent or lease products instead of buying them outright. This ensures that products are returned to the business and can be reused or recycled at the end of their lifecycle.

Eco-Friendly Packaging

Packaging is a major source of waste, but it doesn’t have to be. Eco-friendly packaging solutions, like biodegradable or recyclable materials, can help businesses reduce their environmental footprint and close the loop on waste.

Many companies are now switching to sustainable packaging options that use fewer materials and can be easily recycled. By adopting eco-friendly packaging, businesses can contribute to a circular economy and reduce their impact on the planet.

Case Studies: Businesses That Have Closed the Loop

Many businesses around the world have already begun to close the loop and transition to a more sustainable model. Let’s take a look at a few real-world examples of companies that are leading the way in the circular economy.

Patagonia

Outdoor clothing brand Patagonia has long been a leader in sustainability. The company focuses on creating durable, long-lasting products and encourages customers to repair and reuse their gear instead of buying new items. They also offer a take-back program where customers can return old Patagonia items to be recycled or resold through their Worn Wear program.

By closing the loop on their product lifecycle, Patagonia has significantly reduced waste and demonstrated how businesses can operate in a circular economy.

IKEA

IKEA, the global furniture retailer, is also making strides in closing the loop. The company is committed to using sustainable materials and has launched several initiatives to promote recycling and resource efficiency.

For example, IKEA has a buy-back program where customers can return old furniture to be resold or recycled. They’ve also begun experimenting with furniture rentals, which allows customers to lease items and return them when they’re done, ensuring that products are reused instead of discarded.

Dell

In the tech industry, Dell has been a pioneer in creating a closed-loop system for its products. The company uses recycled materials in many of its products, including plastic from old computers and electronics. Dell also offers a take-back program for customers to return old devices, which are then recycled and used in the production of new products.

By incorporating recycling into its manufacturing process, Dell has been able to reduce waste and minimize its environmental impact.

Overcoming Challenges in Implementing Close-Loop Systems

While the benefits of closing the loop are clear, the transition to a circular economy isn’t without its challenges. Many businesses face obstacles when trying to adopt sustainable practices, but these challenges can be overcome with the right strategies.

High Initial Costs

One of the most common challenges businesses face is the cost of implementing a closed-loop system. The initial investment in sustainable materials, recycling infrastructure, or product design can be expensive.

However, it’s important to remember that these costs often pay off in the long run. By reducing waste and increasing resource efficiency, businesses can save money on raw materials and disposal fees. Additionally, many consumers are willing to pay more for products that are environmentally friendly, which can help offset the initial investment.

Lack of Education and Awareness

Another challenge is getting employees, suppliers, and customers on board with the transition to a circular economy. Change can be difficult, especially when it requires a shift in long-established practices.

To overcome this challenge, businesses need to invest in education and training. Employees should understand the benefits of closing the loop, and suppliers should be encouraged to adopt sustainable practices. Additionally, customers need to be informed about how they can participate—whether it’s through recycling programs or supporting eco-friendly products.

Greenwashing

Unfortunately, not all companies that claim to be sustainable are actually closing the loop. Some businesses engage in greenwashing, where they make false or misleading claims about their environmental impact.

To avoid greenwashing, businesses need to be transparent about their practices and focus on real results. Instead of making vague claims about sustainability, companies should provide evidence of how they’re reducing waste, conserving resources, and contributing to the circular economy.

Best Practices for Businesses Transitioning to a Circular Economy

So, how can businesses successfully close the loop and transition to a circular economy? Here are some best practices to keep in mind.

Design for Longevity

One of the first steps to closing the loop is designing products that last longer. This means using durable materials, making products easy to repair, and ensuring that they can be recycled at the end of their life cycle.

By focusing on product lifecycle management, businesses can reduce waste and ensure that their products contribute to the circular economy.

Build Strong Relationships with Suppliers

To create a truly circular supply chain, businesses need to work closely with their suppliers. This means building relationships with suppliers who prioritize sustainability and ensuring that every stage of the supply chain contributes to reducing waste.

Engage with Customers

Customers play a key role in closing the loop. Businesses need to educate their customers about the benefits of recycling, reusing, and supporting sustainable products. Offering take-back programs, providing repair services, or promoting eco-friendly packaging are just a few ways to engage with customers and encourage them to participate in the circular economy.

The Future of Closed-Loop Systems: Trends and Innovations

The future of closing the loop looks promising, with new trends and innovations emerging to support the circular economy.

Emerging Technologies

Technological advancements are making it easier for businesses to track and reuse materials. For example, blockchain technology can be used to track the lifecycle of a product, ensuring that it’s properly recycled or reused. Artificial intelligence is also being used to optimize resource efficiency and reduce waste.

Policy and Regulation

Governments and international organizations are beginning to implement policies that support closed-loop systems. These regulations encourage businesses to adopt sustainable practices and contribute to the circular economy.

FAQs

What does “closing the loop” mean?

Closing the loop means keeping materials and resources in use for as long as possible. Instead of throwing things away after using them, we find ways to reuse, recycle, or repurpose them. This helps reduce waste and saves resources. It’s part of what’s called a circular economy, where nothing goes to waste.

How is a circular economy different from a regular economy?

A circular economy works like a circle—things are used, then reused or recycled to make new products. In a regular economy, we follow a take-make-dispose model. This means we take resources from nature, make products, and then throw them away when we don’t need them anymore. The circular economy helps reduce waste and protect our planet’s resources.

Why is closing the loop important for the environment?

Closing the loop helps reduce the amount of waste we create and conserves natural resources. By recycling and reusing materials, we can prevent them from ending up in landfills or polluting the environment. It also helps reduce the need to take more raw materials from the earth, which is important for the long-term health of our planet.

How can businesses close the loop?

Businesses can close the loop by designing products that last longer and are easy to repair or recycle. They can also work with suppliers who focus on sustainability, use eco-friendly packaging, and create take-back programs for customers to return used products. These steps help businesses reduce waste and be more eco-friendly.

What can I do as a customer to support a circular economy?

As a customer, you can support a circular economy by choosing products that are made from recycled materials, buying from brands that focus on sustainability, and participating in recycling programs. You can also look for products that can be repaired or reused instead of buying new items. Every little bit helps to reduce waste and protect the environment.

Conclusion

In a world where resources are finite and waste is piling up, closing the loop offers a smart, sustainable solution. By adopting the principles of the circular economy, businesses can reduce waste, conserve resources, and build a healthier planet for future generations.

Now is the time to take action. Let’s work together to close the loop and build a world where nothing is wasted, and everything has value.

This article emphasizes practical examples, actionable steps, and the broader benefits of closing the loop and transitioning to a circular economy.

I’m Clara Whitmore, the girl running the show at “Grammer Grove.” I’ve been playing with expressions and formats to make grammer a whole lot of fun. Over at Grammer grove, we’re here to make your English grammer incredible. Let’s add some professionalism and gratitude to yourwritting together!